Software Description:

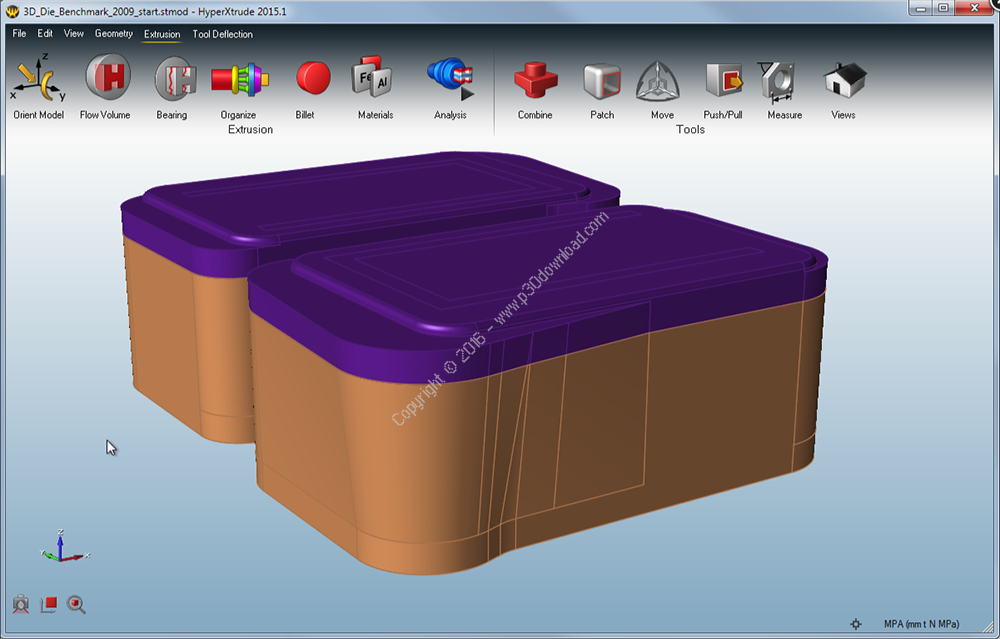

Today’s extrusion companies are forced to produce a higher mixof complex profiles in shorter product development cycles whilesimultaneously reducing their production costs.HyperXtrude is a simulation environment to meetthese needs and increases productivity by analyzing and optimizingextrusion dies, and process conditions.

HyperXtrude is like a virtual press where the user can visualizematerial flow and temperature inside a die during extrusion, andmake necessary changes to ensure balanced flow and eliminateproduct defects. HyperXtrude helps reducing costly die-trials.

HyperXtrude is widely used in the extrusion industry and sinceits inception in 1999, its development is driven by the industryand customer needs.

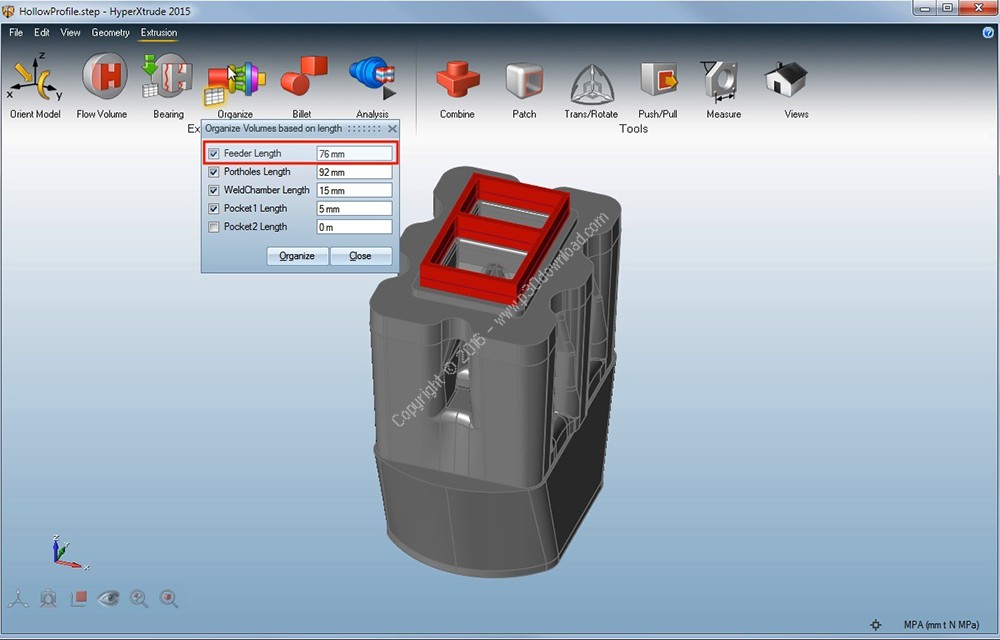

HyperXtrude® 2015 introduces a new CAD interface for HyperXtrudesolver and takes a giant leap to a direct CAD to solution approach.This approach automates and hides the meshing and data deckcreation, and completely relegates it to the background. Hence,users can submit the analysis after creating the CAD model. In thisrelease, interface for steady state metal extrusion is supported.Key features are listed below and they all can be completed in fewmouse clicks.

Metal Extrusion:

– Speed and Performance: Now you can work with large models up to 4million nodes on both Windows and Linux 64-bit platforms.

– Solver Accuracy: Improvements include cone prediction ofprofiles, especially for those with large variation inthicknesses.

– Bearing Optimization: This module determines the imbalance inmaterial flow at the end of the bearing region instead of the exitto improve the accuracy of the bearing optimization.

– Mandrel Offset: In this release, you can mesh the model with themandrel offset and the solver will account for this step in thecomputation. The advantage of including the mandrel offset issavings in time spent in CAD correction.

– Grain Size Computations: A new dynamic recrystallization grainsize model (DRX) accounts for the dependency of grain size onstrain, and temperature-corrected strain rate.

– Automatic Extraction of Flow Volume: A new one-click optionextracts the negative volume for the tool assembly and greatlyminimizes model preparation time.

– Automatic Billet Creation: This option lets you determine abillet center from a die surface or edge. Specify centercoordinates and estimate the upset billet length from the specifieddata.

– One-Click Solid Editing: One-click editing lets you merge orconnect solids with a shared, common surface at the interface ofadjacent solids.

– Geometry Cleanup: Access HX-Geom Cleanup from the Geometry menuto remove edges and sliver surfaces. This option greatly minimizesmodel cleanup time.

– Specifying Billet Taper Data: With the Billet Taper option, youcan specify three types of tapers in your analysis (Axial taper,radial taper, and lateral taper). You can specify the Axial Taperin up to five zones where temperature can vary linearly withdifferent gradients.

– Starter Billet: Using the Billet Taper option, you can specifystarter billets of different lengths and use a different ram speedfor each billet. This data is relevant only for transient,multi-cycle analysis. You can specify up to 5 different initialcycles with varying billet length data. In addition, you can usedifferent axial tapers for each of the initial cycles.

– Super Alloy Extrusion Using Glass Lubrication: The ExtrusionWizard now supports glass lubricated (with glass pad and glasspowder coating) extrusion. Glass lubrication is often used withnickel, titanium, and steel alloy extrusion (requires a customsolver version).

– Fit Material: An improved Fit Material GUI in the HyperXtrudematerial database lets you specify material data interactively orvia the DAT file.

– Improve Mesh: The Extrusion Wizard provides an option to improvethe mesh quality by remeshing the solids based on initiallygenerated mesh.

– Tool Deflection Analysis in User Units: The Tool DeflectionWizard now supports user units. For example, if you set up a modelin British units, your results from OptiStruct will havedisplacements in inches and stresses in ksi.

– HX Job Manager: Added support for this feature lets you submitOptiStruct runs on remote machines.

Polymer Extrusion:

– Performance Enhancements: Now you can work with large models upto 4 million nodes on both Windows and Linux 64-bit platforms.

– Automatic Extraction of Flow Volume: A new one-click optionextracts the negative volume for the tool assembly and greatlyminimizes model preparation time.

– One-Click Solid Editing: The Merge option merges selected solids.The Connect option creates a shared common surface at the interfacebetween adjacent selected solids.

– Easy Geometry Cleanup: The new HX-Geom Cleanup option, accessedfrom the Geometry menu, lets you remove unwanted edges and sliversurfaces, and minimize model cleanup time.

– Tire Extrusion Wizard: The Tire Extrusion Wizard is used tosimulate the extrusion of tire treads. The model-setup feature letsyou create geometry based on a given die configuration oruser-specified solids. This feature includes support of multi-cutextrusion dies, specification of tread and die contours assymmetric or full contours, and automatic report-generation.

– Improve Mesh: The Extrusion Wizard provides an option to improvemesh quality by remeshing the solids based on initially generatedmesh.

– Tool Deflection Analysis Wizard: Solve tool deflection analysiswith OptiStruct. Second order elements are supported, as well aspressures and forces. Loads from a HyperXtrude analysis can bemapped. Contacts between die plates, temperature conditions andother boundary conditions are automatically created.

Installer Size: 549.33 MB

Download Links > Altair HyperXtrude v2015.1 Build 1362 x64 + Crack